Paint Slurry Pumps

50000.00 - 500000.00 INR/Piece

Product Details:

- Head Size Up to 240 Bar

- Theory Other

- Flow Rate Up to 1000 M3/hr

- Material CI/SS

- Structure Screw Pump

- Power Electric

- Product Type Positive Displacement Pumps

- Click to View more

X

Paint Slurry Pumps Price And Quantity

- 50000.00 - 500000.00 INR/Piece

- 1 Piece

Paint Slurry Pumps Product Specifications

- Other

- Up to 240 Bar

- CI/SS

- Gland Packing / Mechanical Seal

- Screw Pump

- High Pressure

- Positive Displacement Pumps

- Other

- Electric

- Other

- Up to 1000 M3/hr

- NETZSCH Green

Paint Slurry Pumps Trade Information

- Cash in Advance (CID)

- 100 Piece Per Week

- 1 Week

- Contact us for information regarding our sample policy

- Asia

- All India

Product Description

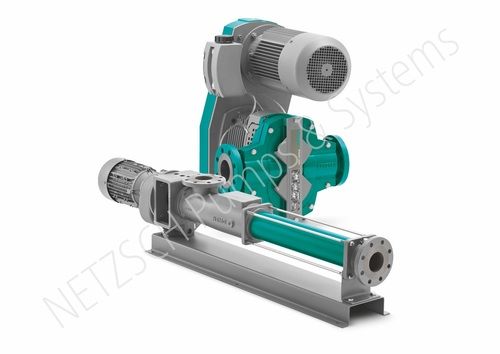

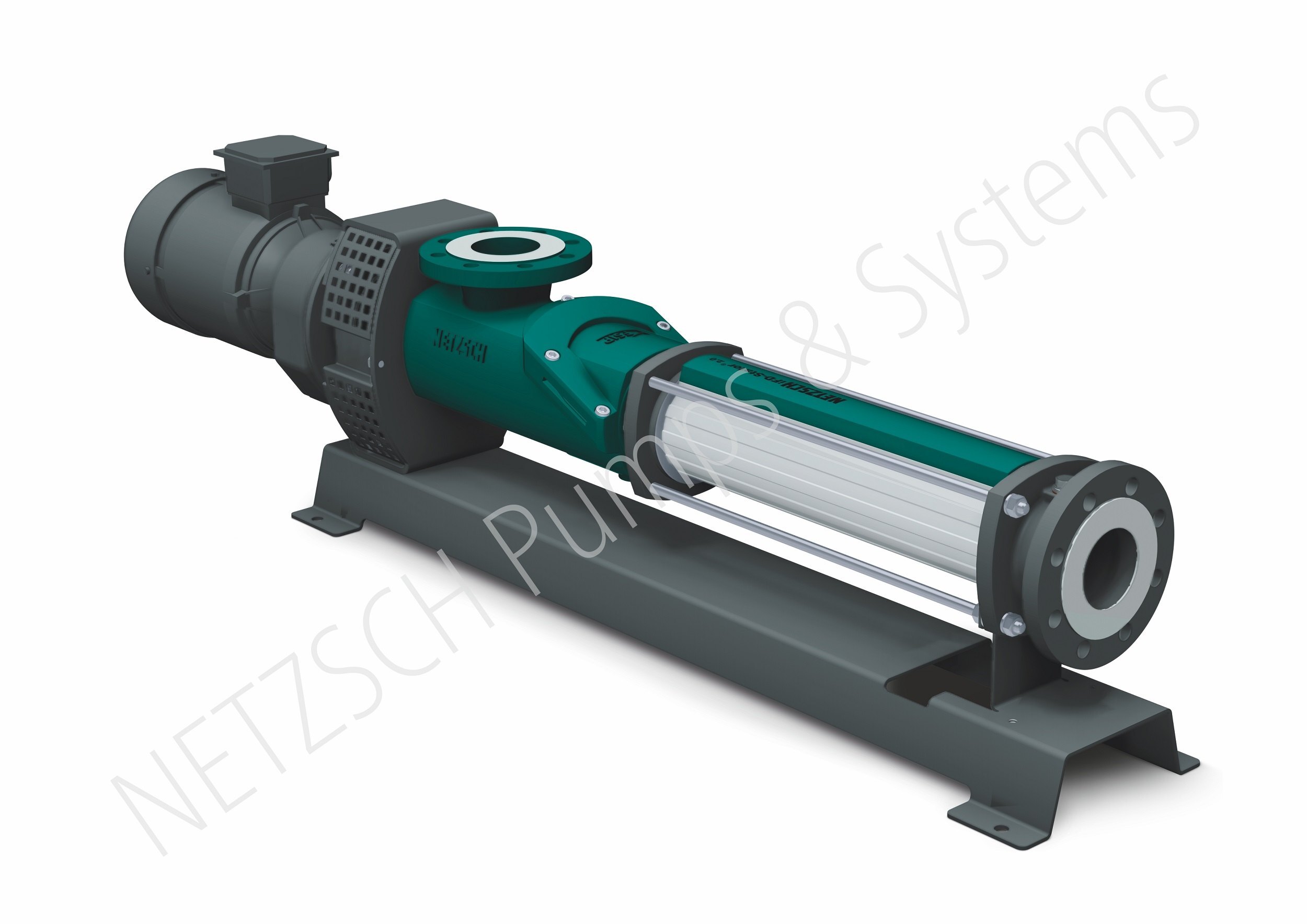

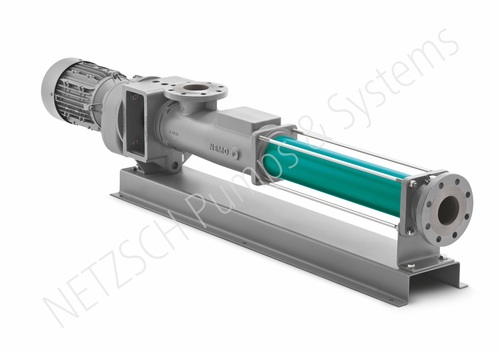

NETZSCH is a leading manufacturer and supplier of an excellent quality range of Paint Slurry Pumps. These are applied in various industries, the Progressive Cavity Pump has been used as a fluid transfer pump for years. These Progressive Cavity Pumps can pump or transfer high and low-viscosity products, with or without solids or long fibers, in suspension.Paint Slurry Pumps Specifications:

|

Brand |

NETZSCH |

|

Condition |

New |

|

Design Type |

Positive Displacement Pumps |

|

Head |

Up to 240 Bar |

|

Max Flow Rate |

Up to 1000 M3/hr |

|

Model |

NEMO |

|

Pressure (Bar) |

Up to 240 Bar |

Paint Slurry Pumps Features:

- Minimal noise level

- Low energy consumption

- High resistance to abrasion and corrosion

- Ability to pump a wide range of fluid viscosities

- Simple installation, operation, and maintenance

- The product remains unchanged during the pumping process

- Simple operation as the single helical rotor rotates inside the double helical, elastomer-lined stator

- The rotor rotates eccentrically in the stator through a series of sealed cavities for 180 degrees therefore progressing the medium from the intake to the discharge end of the assembly

- The volumetric efficiency is directly proportional to the number of rotations of the pump to the size of the cavity formed between the rotor and stator

- Another captivity is created after one is diminished at the same rate resulting in a constant non-pulsating flow

8

Other Products in 'Chemical Pump' category

Get in touch with us