Grinding System

Product Details:

- Theory Other

- Material CI/SS

- Structure Screw Pump

- Power Electric

- Product Type Positive Displacement Pumps

- Fuel Type Other

- Color NETZSCH Green

- Click to View more

Grinding System Price And Quantity

- 1 Piece

- 50000.00 - 500000.00 INR/Piece

Grinding System Product Specifications

- Other

- CI/SS

- Positive Displacement Pumps

- High Pressure

- NETZSCH Green

- Gland Packing / Mechanical Seal

- Other

- Other

- Electric

- Screw Pump

Grinding System Trade Information

- 100 Piece Per Week

- 1 Week

- Contact us for information regarding our sample policy

- All India

Product Description

Product Description

| Condition | New |

| Power Source | Electricity |

| Automatic Grade | Semi-Automatic |

| Product Type | Grinder |

| Brand | NETZSCH |

| Application | Grinding |

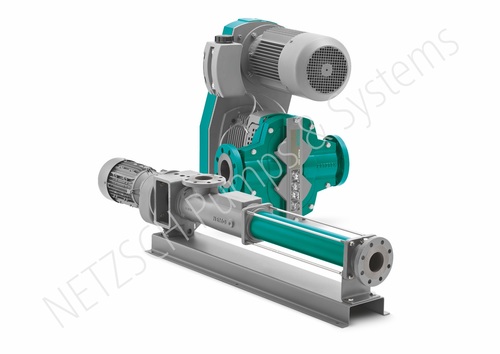

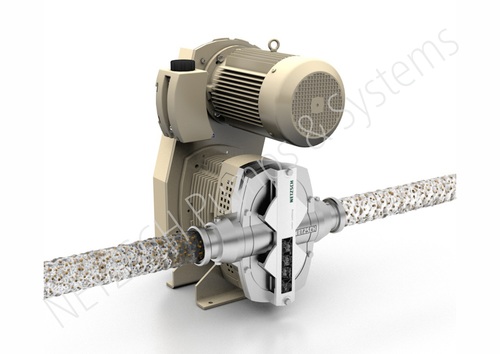

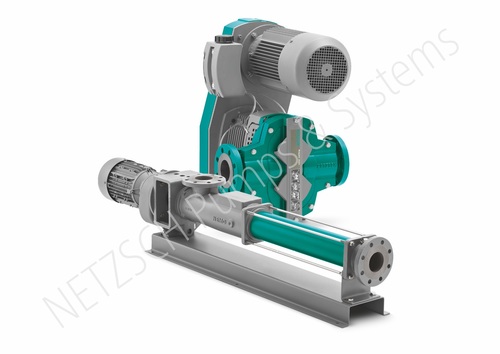

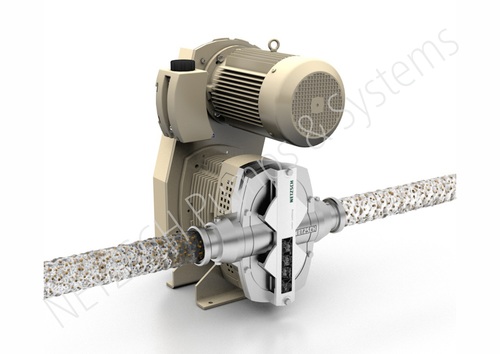

| Model | M OVAS |

Grinding Systems can be used wherever it is essential that solid matter in fluids be broken down reliably to ensure the prevention of pipe clogging and damage to downstream equipment. The special design of the M-OVA housing carries the solids in the waste water flow to the cutting plate, where they are held and chopped by rotating blades. This low-maintenance assembly is designed for sludges with a maximum flow of 300 m3/h and a dry matter content of up to parcentage

Advantages of the NETZSCH M-OVAS:

- high operating safety due to robust construction

- ease of operation and simple maintenance

- low operating costs through high operating efficiency

- optimal price/performance ratio

- Waste water treatment

- Agriculture

- Slaughterhouses and recycling plants

- Canning/tinning factories

- Sugar factories

- Industrial kitchens

FAQs:

Q: What is a grinding system?

A: A grinding system is a type of equipment used to break down solid matter in fluids to prevent pipe clogging and damage to downstream equipment. Grinding systems typically use rotating blades or other cutting mechanisms to chop up and disperse solids in the fluid stream.

Q: How does a grinding system work?

A: The exact workings of a grinding system will depend on the specific design of the equipment, but typically a grinding system will have a hopper or inlet where the material to be ground is fed into the system. Inside the system, rotating blades or other cutting mechanisms chop up the material into smaller pieces, which are then dispersed in the fluid stream.

Q: What are the advantages of a grinding system?

A: Grinding systems offer several advantages, including preventing pipe clogging and damage to downstream equipment, reducing waste volume, and creating a homogenous slurry that can be more easily treated or disposed of.

Q: What industries use grinding systems?

A: Grinding systems are used in a wide range of industries, including wastewater treatment, food and beverage processing, agriculture, and industrial manufacturing.